CALIPER LOGGING

-

Caliper logging of boreholes is commonly conducted to measure variations in borehole diameter over the length of the excavation. Information of borehole diameter, shape and roughness can be used to calculate borehole volume.

-

The Caliper Tool used for this test consists of 3 or 4 independent spring-loaded caliper arms that continually adjust to the size of the borehole as they are pulled to the surface. These arms are opened and closed using a small motor incorporated in the tool. The tool is lowered into, and lifted from the shaft at a controlled rate using a winch unit. The unit includes a depth encoder, which indicates the depth of the probe and a cable tension reading, which can be used to determine when the probe has reached the bottom of the borehole. The depth and diameter are read by a surface data logger unit interfaced with a PC which promptly displays the data to be adjusted and recorded. Computer software performs the analysis and processes the data resulting in a graph of diameter as a function of depth as shown opposite.

-

Such graphs provide indications on the presence of cave-ins, collapse or shale swelling and other geological characteristics in the borehole.

CROSS-HOLE SONIC LOGGING

-

Cross-Hole Sonic Logging (CSL] allows for the detection of concrete defects such as poor quality concrete, soil inclusions, voids, honeycombing and slurry inclusions. This method is applicable to piles of any dimensions and can be used on diaphragm wall or any similar concrete structures. It gives indications of the concrete quality down the entire pile shaft; it does not however provide information about the concrete outside the reinforcement cage and does not clearly identify the type of detected defect.

-

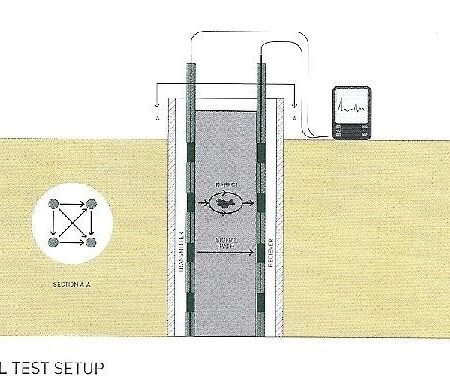

CSL is achieved by the use of sonic transmitter and receiver probes which are lowered down the pile shaft through pre-installed access tubes. An ultrasonic pulse generator sends pulses to the transmitter probe where they are converted into ultrasonic waves that are received by the receiver probe. The propagation time of the ultrasonic signals between the tubes is measured and stored while the meter-wheel provides the corresponding depth. Variations in signal arrival time and strength indicate areas that may require further investigation.

DYNAMIC TESTING-HIGH STRAIN

- The basic purpose of this test is to evaluate pile static capacity, its structural integrity as well as hammer performance, pile stresses and soil characteristics, such as soil damping coefficients. On-site evaluation of the test results by a trained and experienced professional would determine if the pile is to be accepted or rejected.

- The test is conducted by impacting the pile top with a drop hammer from a predetermined height. The impact produces a compressive wave that travels down the shaft of the foundation. Strain transducers and accelerometers are attached to diagonally opposite sides of the pile cap which respectively measure the strain and acceleration induced into the pile. Strain measurements are converted to force and acceleration records to velocities by a Pile Driving Analyzer®. Force and velocity measurements facilitate estimating soil resistance and its distribution.

- The collected test data is analyzed and processed by computer software such as CAPWAP® [Case Pile Wave Analysis Program] to estimate total bearing capacity of a pile or shaft, as well as resistance distribution along the shaft and at the toe, producing the graphs shown opposite.

DYNAMIC TESTING-LOW STRAIN

-

Transient Dynamic Response [TDR] method is a low strain dynamic test which provides a rapid and accurate way of assessing the continuity and integrity of concrete pile foundations.

-

The test is conducted by striking the pile top axially with an instrumented [force response] hammer to induce a longitudinal wave that travels down the shaft. When the wave reaches the base of the pile or encounters an acoustic anomaly, it is reflected back up to the top. A transducer affixed on the hammer and a geophone sensor on the pile top respectively measure the force of the blow and the velocity of the response signal. These signals are digitized and stored on the test unit.

-

The collected data is conditioned, analyzed and processed via computer software to generate the graphs shown one the next page. Trained personnel examine and interpret these graphs to deduce the following information about the tested pile:

-

Pile length, or depth to anomalies

-

Pile head stiffness

-

Pile shaft mobility - which is dependent on pile section and concrete properties

-

Pile toe level

-

Shaft restraints

-

Over break

-

Cracks

-

Reductions in section

-

Zones of poor quality concrete

INTEGRITY TESTING

-

The Pulse Echo Test, also known as Pile Integrity Test, Sonic Echo Test and Low Strain Impact Integrity Test, is a rapid, inexpensive, non-destructive method to check for pile defects such as voids, cracks, necking, inclusions, etc. It determines the pile integrity, dimensions, continuity and pile material consistency by measuring and analyzing the velocity response of the pile induced by the impact of a hand held hammer applied axially and perpendicular to the pile head surface. The stress wave induced by the hammer strike travels down the pile shaft and reflected waves from significant changes in pile shaft acoustic impedance are registered by a transducer held against the pile head.

-

Measured signals are amplified, digitized and stored by the test unit. The data from the test unit is used by computer software to generate velocity-time graph as shown on the next page. Trained technicians interpret such graphs to determine if the pile has any serious defects, allowing quick evaluation and enhancing the reliability of the foundation.

MATERIAL TESTING

Concrete constituents are tested to ensure conformance to project specifications:

-

Physical properties of cement

-

Chemical analysis of aggregates

-

Organic impurities in fine aggregates for concrete

-

Potential alkaline reactivity of aggregates

-

Particle density [spec. Gravity] and water absorption of aggregates

-

Aggregate moisture content

-

Aggregate crushing value

-

Particle size distribution of aggregates

-

Soundness of aggregates

-

Ten percent fines value

-

Aggregate impact value

-

Flakiness index

-

Elongation index

-

Los Angeles abrasion of aggregates

-

Shell content

-

Sulfate content of aggregates

-

Chloride content

-

Admixture test

-

Chemical analysis of water

A trial mix is routinely made for testing purposes to ensure that proposed mix designs meet requirements. The following tests are conducted on ready mix concrete:

-

Slump

-

Temperature upon delivery

-

3 days’ compressive strength [depending on project requirements]

-

7 days’ compressive strength

-

28 days’ compressive strength

-

Durability

-

Initial surface absorption

-

Water permeability

-

Water absorption

-

Rapid chloride permeability

-

In addition to supplying mill certificates for all deformed steel rebar to be used for the fabrication of reinforcement cage, batches are also tested for the following:

-

Tensile strength

-

Bending /re-bending

-

Chemical analysis

QUALITY CONTROL

-

At Construction Piling Company, we take great pride in the quality of work we produce. We spare no effort or expense to maintain our exemplary health, safety, environmental and quality records. Our reputation in our areas of operation and the very high percentage of returning clients are clear indications of our performance. This is all achieved by our very well trained, dedicated and experienced project teams, by maintaining an impressive top of the line fleet of equipment and by a quality department with the highest standards. This quality system is composed of policies, procedures and records that are integrated into everything we do.

-

Though continuously improving, this system has provided us with a robust framework that allows for smooth operations and facilitates consistency in project quality control and services.

-

The characteristics that compose and define our proactive quality system and associated processes are as follows:

-

People are behind the success of our business. Proper recruitment, training and a generous incentive program bring out the best in our employees.

-

We hold individuals and groups responsible for achieving the expected level of quality.

-

Clear, concise and practical quality policies and standards and process end goals.

-

A clear, well organized, carefully planned system of verification and inspection.

-

A corrective and preventive action system that minimizes or eliminates the repetition of non conformance and reduces rework.

-

Continuous review and update of the whole system.

-

Conformance is the measure of quality; hence quality requirements should be clear and verifiable so that they are easily understood by all parties. Construction Piling Company puts into practice an effective quality control system implemented by qualified engineers to observe, monitor, verify and inspect all definable features of work on a project in order to assure conformance.

-

Quality and Inspection and Testing Plans are developed specifically for each project to encompass all project quality assurance requirements. Experienced test technicians are directly involved in all testing operations, while an alert team of quality control engineers observe and ensure that all test setups, piling operations and activities comply with project requirements. Comprehensive piling records are punctually completed, reviewed for accuracy and filed by the quality assurance department.

-

According to project requirements, various tests, measurements and inspections are conducted to ensure the integrity and reliability of the constructed piles. Material tests are performed on concrete, its constituents and on steel to be used for the fabrication of the reinforcement cages. All finished piles are inspected for verticality and location and tested for integrity. A percentage of all other piles are subjected to other types of testing as required.

-

Construction Piling Company performs all static load tests and inspections in witness of the consultant representative and the expert assistance of a third party when and if required. A qualified, certified and approved third party performs all other material and pile tests.

-

The sampling frequencies for these tests are determined by the project specifications or by referenced standards. All required testing is clearly identified and listed in the Project Inspection and Testing Plan for ease of reference and control.

STATIC LOAD TESTING

Static Load Test [SLT] is the most reliable method of determining pile load capacity. It is the most fundamental form of pile load test and is considered as the bench-mark of pile performance. It involves the direct measurement of pile head displacement in response to a physically applied test load. Testing a pile to failure provides valuable information to the design engineer and is recommended for load tests performed prior to the foundation design or working piles construction. This method is applicable to all types of piles regardless of their method of installation. Piles can be tested for:

- Compression

- Lateral

- Tension