At Construction Piling Company, we take great pride in the quality of work we produce. We spare no effort or expense to maintain our exemplary health, safety, environmental and quality records. Our reputation in our areas of operation and the very high percentage of returning clients are clear indications of our performance. This is all achieved by our very well trained, dedicated and experienced project teams, by maintaining an impressive top of the line fleet of equipment and by a quality department with the highest standards. This quality system is composed of policies, procedures and records that are integrated into everything we do.

Though continuously improving, this system has provided us with a robust framework that allows for smooth operations and facilitates consistency in project quality control and services.

The characteristics that compose and define our proactive quality system and associated processes are as follows:

- People are behind the success of our business. Proper recruitment, training and a generous incentive program bring out the best in our employees.

- We hold individuals and groups responsible for achieving the expected level of quality.

- Clear, concise and practical quality policies and standards and process end goals.

- A clear, well organized, carefully planned system of verification and inspection.

- A corrective and preventive action system that minimizes or eliminates the repetition of non conformance and reduces rework.

- Continuous review and update of the whole system.

Conformance is the measure of quality; hence quality requirements should be clear and verifiable so that they are easily understood by all parties. Construction Piling Company puts into practice an effective quality control system implemented by qualified engineers to observe, monitor, verify and inspect all definable features of work on a project in order to assure conformance.

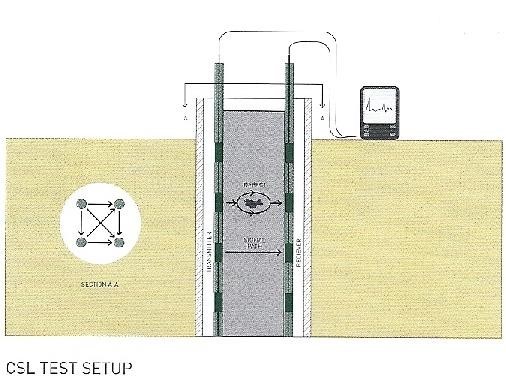

Quality and Inspection and Testing Plans are developed specifically for each project to encompass all project quality assurance requirements. Experienced test technicians are directly involved in all testing operations, while an alert team of quality control engineers observe and ensure that all test setups, piling operations and activities comply with project requirements. Comprehensive piling records are punctually completed, reviewed for accuracy and filed by the quality assurance department.

According to project requirements, various tests, measurements and inspections are conducted to ensure the integrity and reliability of the constructed piles. Material tests are performed on concrete, its constituents and on steel to be used for the fabrication of the reinforcement cages. All finished piles are inspected for verticality and location and tested for integrity. A percentage of all other piles are subjected to other types of testing as required.

Construction Piling Company performs all static load tests and inspections in witness of the consultant representative and the expert assistance of a third party when and if required. A qualified, certified and approved third party performs all other material and pile tests.

The sampling frequencies for these tests are determined by the project specifications or by referenced standards. All required testing is clearly identified and listed in the Project Inspection and Testing Plan for ease of reference and control.