BENTONITE SUPPORT

- Drilling mud or slurry such as bentonite is mostly used for drilling support in situations where the bore hole is unstable. A positive head of bentonite suspension above the water table is maintained during the drilling process, thus providing continual support to the borehole walls. Fluid concrete displaces the clean bentonite which is collected, cleaned and reused several times before it is discarded.

- The auger is simultaneously withdrawn at a rate synchronized with the concrete pumping process such that the pumped concrete promptly occupies the displaced volume exerting a positive pressure, which assists in the extraction process whilst maintaining lateral support to the surrounding soils. The steel reinforcing cage (if required), is then immersed into the wet concrete.

CAST-IN-SITU BORED PILES

-

This type of pile installation is used to replace soil removed by drilling rather than occupying the space of displaced soil as in driven piles and thus, it mostly relies on end-bearing capacity of the earth layer at the drilled depth.Bored piles provide the largest pile dimensions and thus the highest load bearing capacities.

-

One method of installation is to drill a shaft using a continuous auger with a hollow stem at its center which is later used to grout the drilled shaft. This method is known as Continuous Flight Auger.

-

Another technique is to drill the shaft, insert the reinforcement steel cage (if required) and then pour concrete under pressure to fill the entire shaft space. The shaft is drilled using an auger in dry land conditions and a drilling bucket in wet land conditions.

-

When shaft wall support is required, the drilling process takes place inside a steel casing or with the aid of drilling slurry such as Bentonite.

DEEP FOUNDATION PILING

-

Construction Piling Company main area of specialization is in deep foundation piling and associated works. The solutions presented hereinafter describe the main services that CPC offers. We also offer a variety of other solutions that are infrequently used in the area. With ample resources in addition to our experienced engineers and designers, we are able to provide innovative solutions to nonstandard deep foundation issues.

-

The many available types of piles and associated construction methods are mainly used for foundation load transfer and earth retention systems. They are used in marine-based structures and in land-based structures where the surface soil layers cannot provide the required load-bearing capacity. In all situations, piles are utilized to transfer lateral, vertical or a combination of both loads through weak soil layers to a suitable bearing layer.

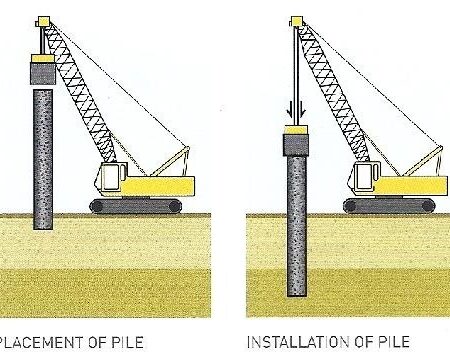

DRIVEN PILES

-

Prefabricated Steel, wood or concrete piles are driven into the ground using impact hammers.Driven piles provide the fastest deep foundation solution and have the advantage over drilled shaft piles of higher skin friction, thus increasing their load bearing capacity.

-

They are suitable for most land and marine applications and offer a high performance piling system with upto 1000 tons/pile design load capacity.

-

Steel piles such as sheet and H-Beam piles (soldier piles) to form earth retention and excavation support walls, are the most commonly used. Wood and reinforced concrete are used in other limited conditions.

PILE CAPS & CAPPING BEAMS

-

Pile Caps connect groups of piles to distribute loads over the capped piles.Pile heads are stripped to expose the steel reinforcement to be projected into the pile cap. Steel reinforcement is placed at the desired location and a large concrete block is formed. Pile caps can assume a variety of shapes, but they are mostly rectangular or triangular.

STEEL CASING SUPPORT

-

Steel Drill Casing is advanced into the ground using a vibratory hammer leaving a 1-meter protrusion. The casing is driven about 50 cm into hard stratum to provide shaft wall support during the drilling process. After drilling to the specified depth, the bottom of the shaft is cleaned using a drilling bucket, the shaft depth is measured and caliper logging is performed to ensure that no major collapses have occured in the borehole walls under the casing. Steel cage reinforcement fitted with spacers (to provide uniform concrete cover) is placed within the borehole using a crane and concrete is poured into the shaft under high pressure using a tremi pipe and a suitable concrete pump. The temporary casing is then gradually extracted from the ground (for temporary casing installations only) by vibrating, oscillating or rotating and load is transferred to the formed concrete pile shaft.

-

The same procedure is followed for permanent casing foundation piles, except that the casing is not extracted.