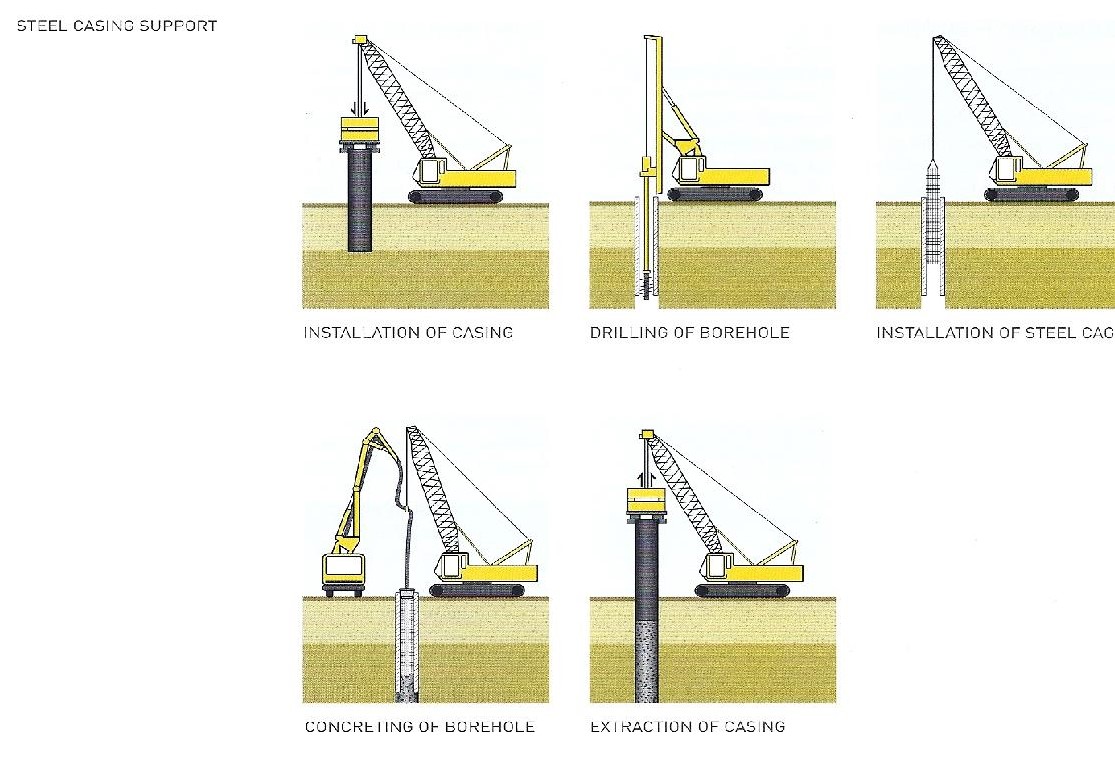

Steel Drill Casing is advanced into the ground using a vibratory hammer leaving a 1-meter protrusion. The casing is driven about 50 cm into hard stratum to provide shaft wall support during the drilling process. After drilling to the specified depth, the bottom of the shaft is cleaned using a drilling bucket, the shaft depth is measured and caliper logging is performed to ensure that no major collapses have occured in the borehole walls under the casing. Steel cage reinforcement fitted with spacers (to provide uniform concrete cover) is placed within the borehole using a crane and concrete is poured into the shaft under high pressure using a tremi pipe and a suitable concrete pump. The temporary casing is then gradually extracted from the ground (for temporary casing installations only) by vibrating, oscillating or rotating and load is transferred to the formed concrete pile shaft.

The same procedure is followed for permanent casing foundation piles, except that the casing is not extracted.